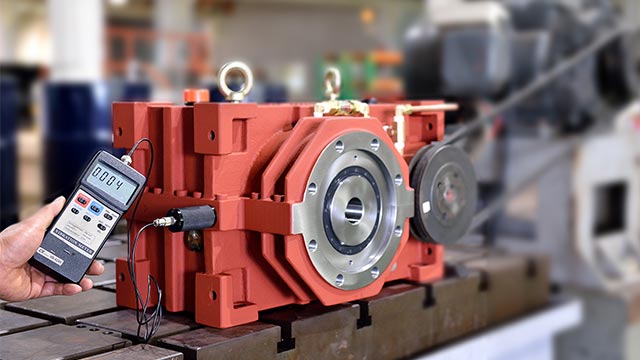

Our quality control department is fully equipped with advance gear inspection instruments introduced from Japan as well a series of precision inspection instruments. SUN LUNG's quality control staff is also well trained for rigorous quality control of all aspects.

LEADING VALUE WITH INNOVATION

Accuracy Meets Din Class 3~4

To ensure our gears reach the highest accuracy standards, SUN LUNG's technological department has spent great efforts in researching gear forming technologies.

Furthermore, we also have deeply researched stress / strain theorem on metallic materials, material structure and heat treatment technologies, etc. Based on our more than 50 years experience in gear manufacturing capabilities have reached international levels. Also,as a result of these remarkable efforts, Sun Lung's gears meet DIN class accuracy.

Gear Precision Comparison Table

( *SUN LUNG Accuracy Meets DIN Class 3~4. Please scroll the table to right and left.)

| Country | Code | Precision | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Germany | DIN | 1 | 2 | 3* | 4* | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Japan | JIS | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||

| USA | AGMA | 16 | 15 | 14 | 13 | 12 | 11 | 10 | 9 | 8 | 7 | 6 | |

| USA | ANSI | 4 | 3 | 2 | 1 | ||||||||

| UK | BS | A1 | A2 | B | C | D | |||||||

| France | FN | A | B | C | D | E | |||||||

Diversified Dynamic Gear Profile Technology

-

1

-

2

-

3

-

4

-

5

-

6

-

7

STRICT QUALITY CONTROL AND PRECISE INSPECTION

In addition the most comprehensive range of world famous machining equipment, SUN LUNG has also set up strict quality inspection standards to fully control the quality at each step throughout the gear manufacturing process.

Detailed inspections and tests conducted from material incoming, manufacturing process, heat treatment quality to final product accuracy.