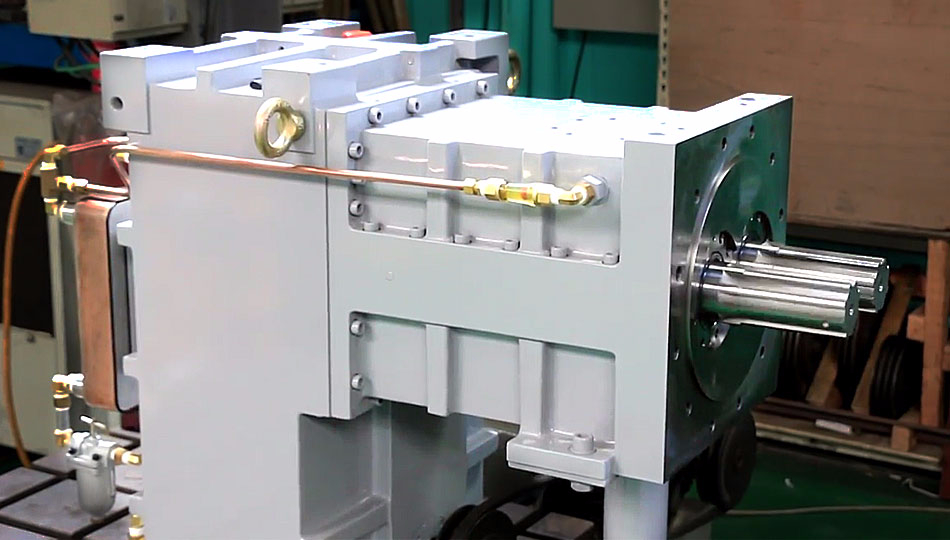

Gearbox for Counter-rotating Conical Twin Screw Extruders

This twin screw extruder gearbox applies the advantages of steady transmission and high loading capability of conical gears to optimize the features of plastic products. The conical gear precision hobbing and grinding are the core technologies. The conical twin screw gearbox are precisely grinded with special machining facilities, customized programs and strict assembly tolerance controlling technologies.

This twin screw extruder gearbox is designed according to the latest principles of AGMA. The structure is composed of deceleration and allocation sections. With innovative breakthrough of conical gear grinding programs, the gearbox performs high transmission efficiency, high torque, high steadiness, low noise and low energy consumption on plastic extruders.

These gearboxes find widespread applications in various industries, including extruders for pipes, sheets, profiles, decorative material, and flooring material, etc.

FEATURE

- High Precision Grade (DIN 1~3)

- High Transmission Efficiency (>97%)

- Long Lifetime Usage

- High Torque (> 11,000Nm)

- Low Operation Noise (< 70dB)

- Low Friction & Energy Consumption